What will set your barrel-aged beer apart from all others?

Black Water Barrels Stavers??? have been developed from years of research, testing, tasting and toasting to help our customers go ‘beyond the barrel’ and achieve outstanding and unique to their brand flavor, color and sensory profiles for their spirits, as well as for wine and beer.

An invitation for Craft Breweries

To test and compare outcomes with and without our Stavers??? oak aging barrel inserts.

Barrel-aging Beer

“From imperial stouts to lagers, almost every beer style on Earth is now being aged in wood. And just as bourbon barrel aging has caught on among winemakers, many craft brewers are using old whiskey barrels (and rum barrels and tequila barrels and wine barrels) to add layers of nuance to their brews. They???re also experimenting with different woods, aging durations, and barrel additions like fruit and spice.”

-Food and Wine

Learn More: “25 Exceptional Barrel-Aged Craft Beers”

Adding Oak

Oak adjuncts or inserts have long been used in the large scale production of white wines in steel tanks to bring that oak flavor and layers to some of the world’s most popular wines. In recent years, the use of staves with custom chars and toasts has become the hallmark of post-maturation or “extra oaking.”

Our Black Water Barrels Stavers??? program is crafted specifically for enhancing the barrel and tank aging of spirits with affordable and easy options that make it possible for the smallest craft producers as well as bulk contract producers to create new and unique products with minimal cost.

Stavers??? make it feasible and easy to enhance products and improve their profitability

in many ways, including:

- Aging acceleration. Reducing time in barrel to achieve superior oak flavors, colors and sensory characteristics from Bourbon or any other barrel aged spirits or craft beers.

- Clearly delicious colors. We all know that most of the flavor and colors comes from the barrel. What goes into a charred new American oak barrel is clear as white dog, comes out brown/amber and so much smoother and mellower than it went in.

- Precision-control of flavor profiles and variations. With Black Water Barrels Stavers??? distillers, brewers and winemakers have more options, more control, more flavors and sensory finishes and complexities to achieve product distinction and customer appeal.

Understanding Oak

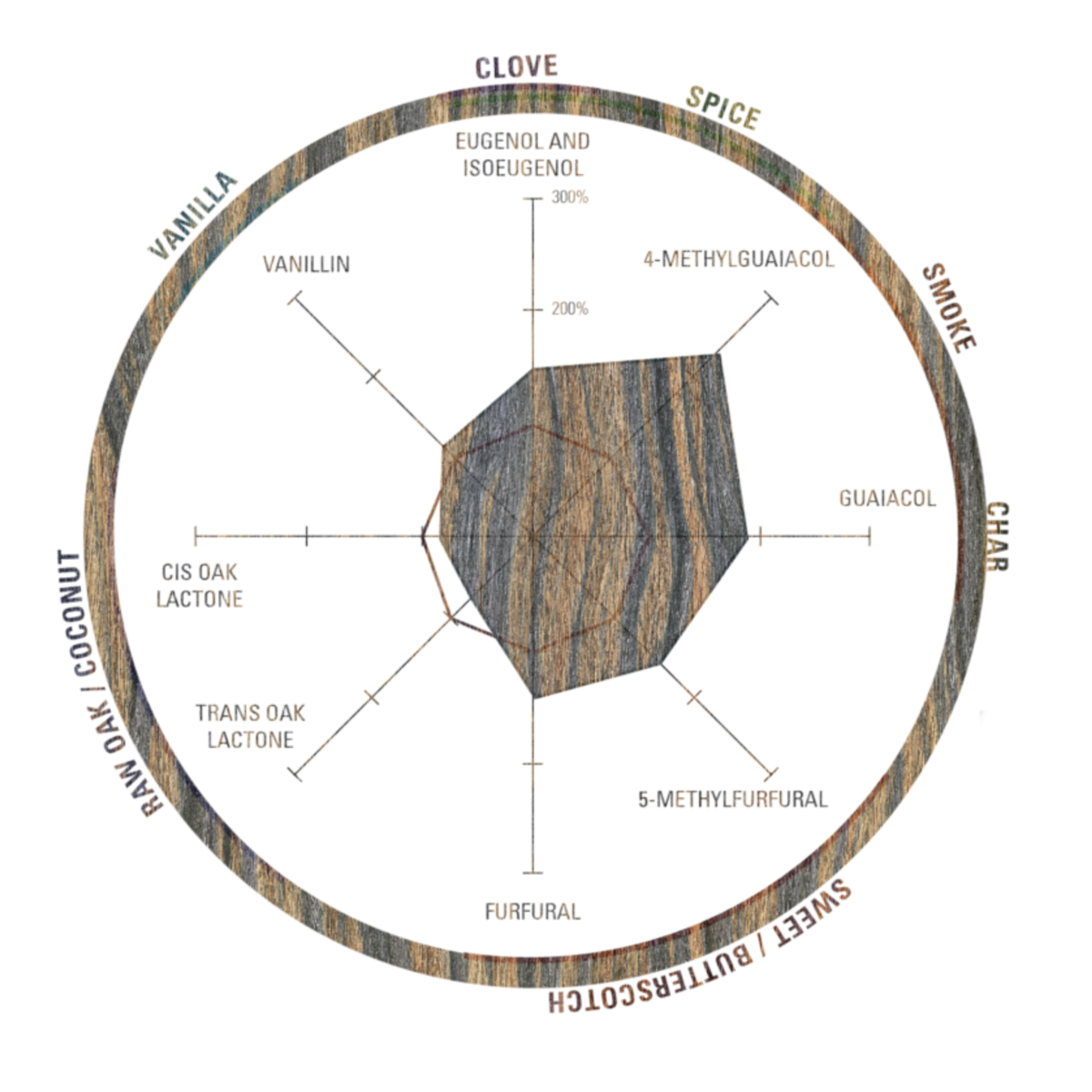

Understanding Oak Variants and Flavor Profiles involves learning a bit about wood chemistry and the factors that contribute to the flavors, sensory perceptions and essential for brown spirits–the color.

That’s why we are creating an easy and informative way for you and your team to understand more of the possibilities .

The Black Water Oak Aging Academy is coming soon, right here.

How

Stavers???

Save

Time,

add

Flavor,

Color

and

Texture.

Overview of Products

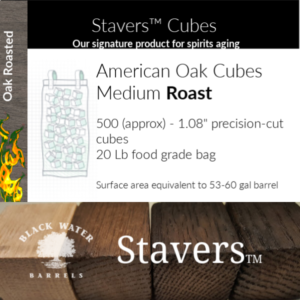

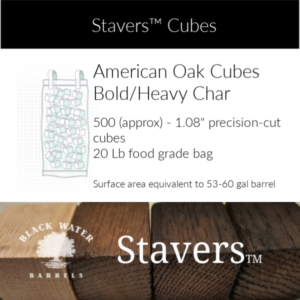

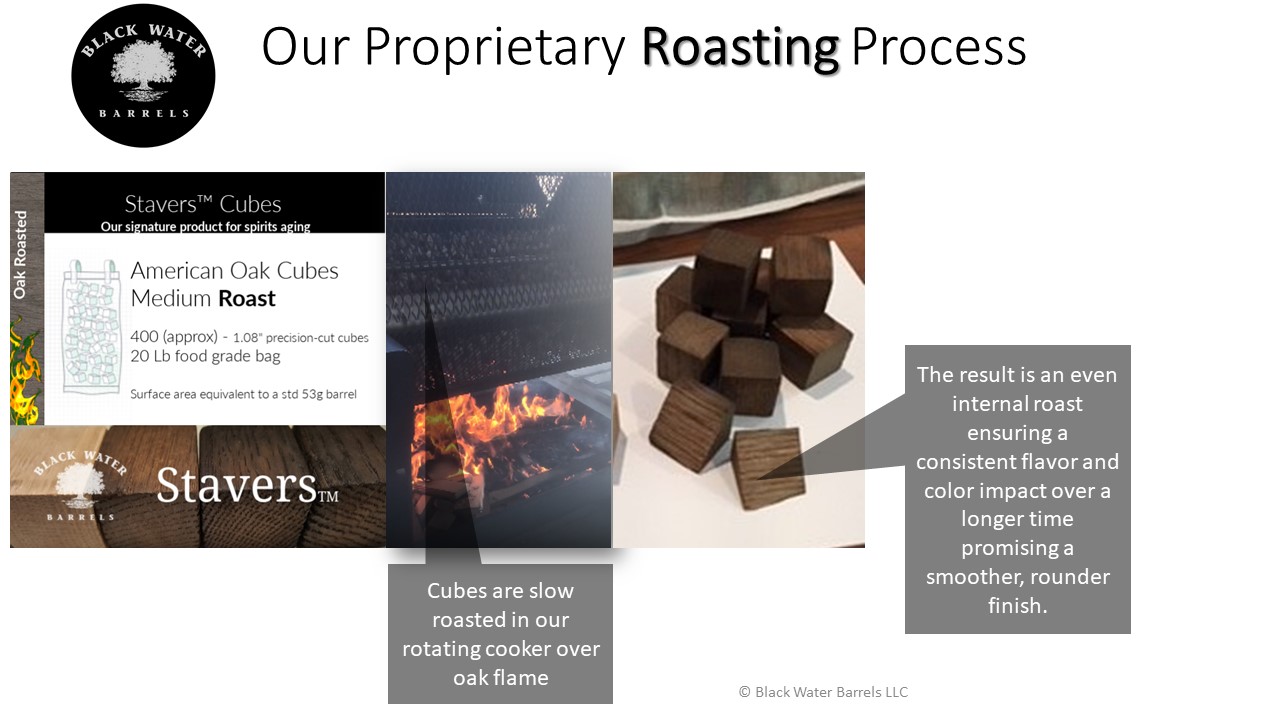

Stavers??? Cubes

Our most unique new product for aging spirits.

Roasted or Charred 1-1/8″ New American Oak Cubes in a 20 lb bag ready for insert into a tank, or as individual cubes put inside a barrel. Available in our proprietary slow roast which imparts consistent flavor for longer duration, or our Bold/Heavy Char for super accelerated aging, as well as for more complex layering.

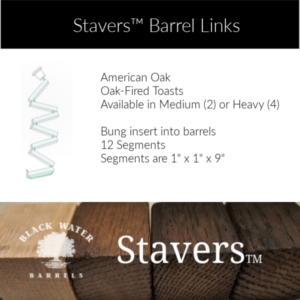

Stavers??? Barrel Links

Designed for easy insert into barrels for all or just a short-period of the maturation process. American Oak stave segments in a food-grade link, Twelve (12) 9″ segments ready to insert through the bung hole to introduce an additional 3.16 square feet of wood surface area to your liquid. Medium or Bold/Heavy Toast. Other toast options by request.

Stavers??? Fan Tank Pack

Twelve 32″ oak fire toasted staves connected as a fan for dropping into tanks. Each fan pack provides 12 sq feet of wood surface area for liquid contact– the equivalent of 3.5 times the amount of oak of a single barrel.

Available in Medium and Bold/Heavy toasts. Other toast recipes by custom minimum order.

American Oak Custom Options

Contact Us To Discuss

French Oak Options

Now available by special order.

Flavor Is In Your Control

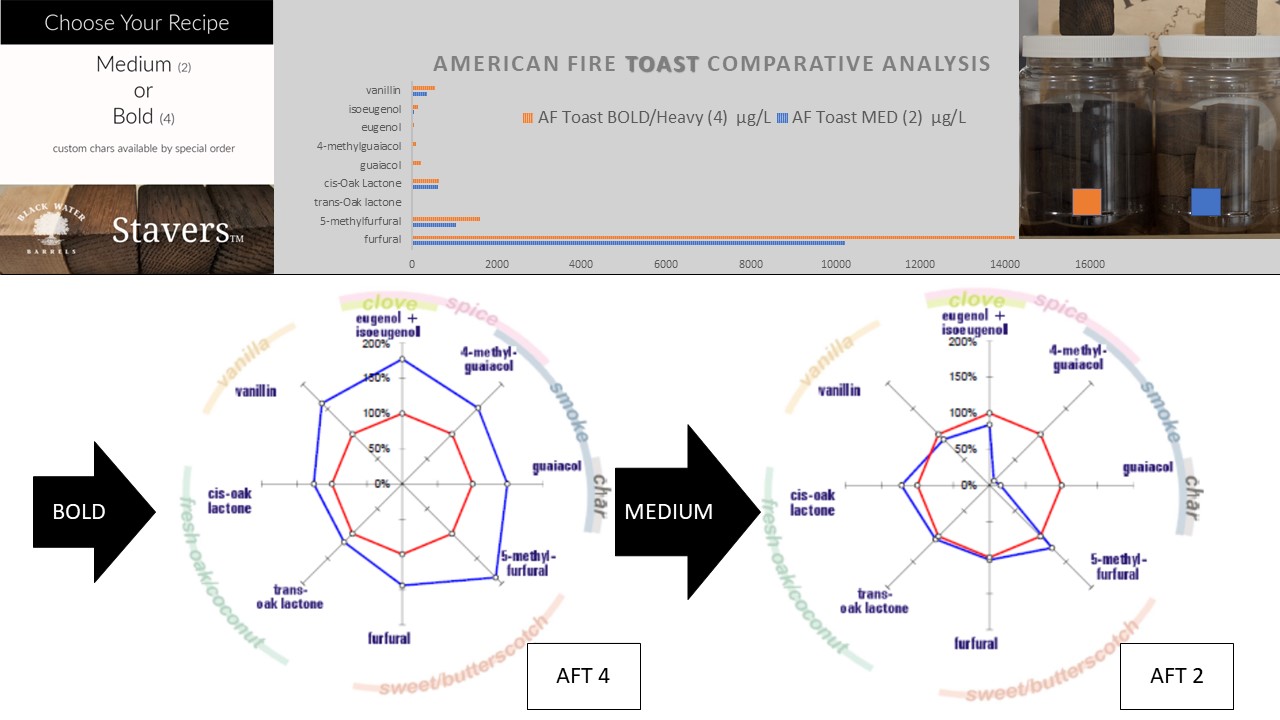

With all of the choices, there are also infinite possibilities for you to enhance the flavor, color and sensory complexities of your “juice.” We’ve conducted wood analysis based on control tests to help you understand how various cook methods and temperature finishes. While aging in charred oak and oak variants factor most into the taste and product finish, additional factors like, dosage (amount of oak), duration (time in barrel/tank), wood surface area (staves vs cubes), not to mention your ingredients, recipes and distillation techniques all matter.

We’ve developed Stavers??? to allow distillers allow enhanced aging of bourbon in barrels to achieve the color and flavors you want with less time in the barrel. This offers a significant opportunity for cost savings, along with the opportunity to bring new flavors and mouthfeel taste to finish your barrel aged products, whether bourbon, all barrel-aged spirits, craft beer or wine.

So while the temperature and humidity of the aging facility–the orange bar below– has a significant impact on aging. That’s not always something 100% in your control.

The critical outcomes of aging you can improve.

- Type of Wood* 15%

- Wood Char 30%

- Duration (time in barrel or contact with wood) 20%

- Dosage (amount of wood surface contact) 20%

- Temperature and Humidity 30%

* Wood type not factored into percentages since American Oak is required for aging bourbon. Black Water makes premium quality American Oak barrels that adhere to Bourbon whiskey requirements that they be new with inner surfaces that have been charred. Most other whiskeys and non-whiskey spirits are not required to use new, unused oak barrels; nor do the oak barrels have to be pre-charred. Our Stavers program has been created using the same American white oak we use for our barrels, but we are also offering options in imported French for post-maturation finishing of bourbons, as well as other spirits, craft beers and wine.

We encourage you to test, taste and tweak to find your finish that will appeal to your customers and drive your profitability.

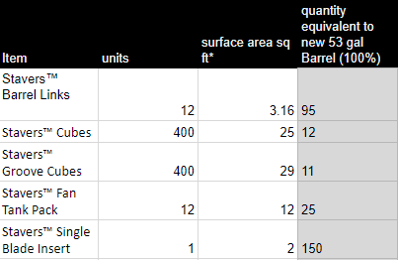

Determining ratios of wood to liquid

Dosing

The amount of oak to liquid surface area is another key factor in aging.

Within the descriptions of each Stavers???product we have included square feet of surface area. While cook and duration of contact are variables, so can dosing–or the amount of oak to liquid.

As a guide, we have estimated the quantity of each Stavers??? product that would be the equivalent to the oak surface of a new barrel.

More of what you need to know about oak, barrels and aging alcohol

Learn More Now

Just Ask

We know you have questions and we are here for you to answer or direct you to resources to help.